ABB has been in the energy business for nearly 130 years. Our products and solutions help customers along the entire energy value chain to extract, transform and use energy effectively and to increase industrial productivity in a sustainable way.

Mitigation of climate change is likely to be the most complex, long-term energy challenge that societies need to address and solve within the coming decades. With more than 80 percent of primary energy supplied by oil, coal and natural gas, and an increasing demand for energy, mostly in emerging economies, greenhouse gas emissions reach new record levels every year.

The link between energy efficiency, renewable energy and mitigating climate change is clear. According to the 2011 World Energy Outlook, published by the International Energy Agency, more than 70 percent of projected CO2 emission reductions by 2020 can be delivered by energy efficiency. A combination of energy efficiency measures and renewable power generation could deliver almost 70 percent of the required emissions reduction over the next two decades.

Energy efficiency and renewable energy also contribute to resolve other major energy-related challenges such as energy poverty, resource depletion and security of supply.

ABB’s Growth Strategy 2011–2015 identifies mitigation of climate change, renewable energy and energy efficiency as key drivers and growth opportunities for our business. Already, nearly 60 percent of our revenues are related to products and services in our energy efficiency portfolio that help customers save energy and reduce greenhouse gas emissions. ABB has created a dedicated Energy Efficiency industry sector initiative to bring the full potential of our portfolio to address opportunities to improve energy efficiency and mitigate greenhouse gas emissions.

During 2011, the initiative began working with ABB’s businesses and geographies to launch comprehensive energy efficiency “solution sets” for sectors as diverse as printing and vehicle assembly. Each sector has unique energy challenges. However, many share inefficiencies in their operations or facilities which can be addressed through proven solutions.

In a similar way, ABB offers broad, cross-functional solution sets of products and services to the wind, water and solar industry sectors, as well as rail. Rail is becoming an increasingly important solution for sustainable mobility, helping to mitigate emissions as well as noise and congestion, as urbanization grows at historic rates.

In 2011, ABB won an order worth around $1 billion to supply a power link connecting offshore North Sea wind farms to the German mainland grid. This was the largest power transmission order in ABB’s history. It will deploy the world’s largest offshore HVDC (high-voltage direct current) system with a rating of over 900 megawatts (MW), keeping electrical losses to less than 1 percent per converter station. The completed link will be capable of supplying more than 1.5 million households with wind-generated electricity and help to avoid more than three million tons of carbon dioxide emissions per year by replacing fossil fuel-based generation.

ABB is a global leader in the development of smart grid technologies. These solutions will help create a lower-carbon power supply system by enabling more distributed generation, more power generated from renewable sources and a two-way grid that can receive as well as deliver reliable power.

In addition to our robust energy efficiency portfolio, ABB continues to make research and development investments as well as exploring early stage technologies and business processes through venture capital activity. Past activities have ranged from e-mobility to solutions for energy efficiency in data centers and smart grid communications.

Addressing climate risk

Potential climate change risk in ABB’s operations is addressed in our comprehensive Enterprise Risk Management process. A wide array of risks is mapped at country, regional and divisional level and a consolidated risk mapping is made at Group level. Reviews of facilities are made annually or biennially. All facilities are required to develop, implement and test business continuity plans. The risk management process has not identified any significant climate change-related physical risk to ABB’s operations. Issues considered include increased storm activity, heavy precipitation, floods or rising sea levels, availability and quality of water supply, and risk of disease/pandemic. Neither have we identified any regulatory risks related to our products, with the potential exception of further regulations related to the use of SF6 in electrical equipment.

Working with partners to build capacity

In 2011, ABB published one of the most comprehensive overviews of energy efficiency in industry and utilities, Trends in Global Energy Efficiency. This publication is a contribution to raising awareness about the importance of using energy more efficiently and the opportunities that exist for industry and power utilities.

The first part of the report measures and analyzes the attitudes and ambitions of business around the world regarding energy efficiency. The second part provides a global overview of energy efficiency in industry and utilities, as well as in-depth reviews of the countries which collectively account for 75 percent of the world’s energy consumption.

At country level, ABB works with a variety of partners, including policy makers, non-governmental organizations, academic institutions, industry peers and customers to raise awareness about technology solutions for improving energy efficiency, to share understanding about the risks and opportunities of different policy approaches, and to test technical solutions. For example, ABB in Italy organized an energy efficiency workshop where CEOs and top management of Italian public and private entities met international experts to examine the international energy situation and energy efficiency solutions in Italy. ABB also collaborates with learning institutions and industrial partners in Sweden, US, Denmark, Germany and Italy to investigate smart grid concepts, to build understanding of how today’s grids can evolve to more interactive networks.

ABB participates in the World Economic Forum’s steering committee for energy efficiency and contributes to its New Energy Architecture study. This report addresses the need for a rapid transition towards a new energy supply system with reduced carbon intensity, and how this should be managed to minimize economic, social and technological risks.

Concrete action to reduce our climate impact

ABB in Italy is pursuing a “green fleet” policy for company personal cars and service cars, targeting an emission reduction of 1,000 tons of CO2 per year. The first step in the program is the introduction of a new range of company cars with average emissions of less than or equal to 150 gCO2/km. This choice required a complete revision of the company car offer and the introduction of several new car models including, for the first time, hybrids. With this choice, ABB Italy estimates that in the years 2011–2012 the average emission per car within the offer will decrease from 148 gCO2/km to 140 gCO2/km, substantially closer to the objective that the EU imposed on car manufacturers, of 130 gCO2/km by 2015. The program is supplemented by the introduction of eco-drive modules within the safe-driving courses program promoted by ABB in Italy and the distribution of tips for eco-driving to all employees.

ABB in Benelux received its CO2 awareness certificate from Dutch railway infrastructure company ProRail in March 2011. The CO2 awareness certificate scheme aims to encourage suppliers to become more active and aware of their own greenhouse gas emissions. To achieve the certificate, ABB in Benelux established its baseline carbon footprint, agreed CO2 reduction objectives based on their seven sites in Benelux, undertook internal and external communications about the project, and agreed to participate in external CO2 reduction collaboration initiatives.

The CO2 emission reduction activities undertaken by ABB in Benelux during 2011 included energy efficiency programs at all sites, switching to 100 percent certified renewable energy, thereby saving 41 percent of their 2009 carbon footprint, and reducing emissions from car travel by switching to the use of e-cars for inter-office travel and boosting the use of videoconferencing.

Energy efficiency begins at home

At ABB, we aim to steadily increase the efficiency of our own operations, including through the use of our own products. We set ourselves the target of reducing the energy we use as a company by 2.5 percent per employee per year for 2010 and 2011. To implement the objective, our 23 most energy-intensive production sites were required to conduct energy audits and all sites were required to develop an energy saving program.

By the end of 2011 we had achieved our energy efficiency objective, reducing energy consumption per employee by 5.5 percent from 2009. Absolute direct energy consumption (oil and gas) was almost unchanged in 2011, compared with 2009, despite significant increases in production and employee numbers. Electricity consumption increased by approximately 10 percent, in absolute terms, from 2009 to 2011, whereas electricity consumption per employee remained stable. We expect to see further improvements in energy efficiency as energy savings programs gain further traction.

Emissions of SF6 increased six percent year on year, less than the 10 percent increase in SF6 handling at our facilities. We continue to pursue emission reduction programs at different sites, with actions ranging from improved handling and inventory procedures to leak detection and improvements in storage methods. However, challenges remain to ensure appropriate handling procedures at both ABB and customer sites.

We are working to improve our data collection around transport emissions, from our own fleet, from transport of our goods by external suppliers and from business air travel.

During 2011, we finalized the development of key performance indicators to monitor the environmental impact of transport of goods and completed pilot projects in Italy, Saudi Arabia and the US to help us understand how these indicators can be applied practically for both domestic and international transport. Draft guidelines for the application of these indicators have been developed and are still in a testing phase, with a proposed release date in 2012. Carbon dioxide emissions from cross-border transportation and air and sea transportation have been collected and are under evaluation. To guide and coordinate Group transport and logistics strategy and programs, we have formed a Transportation Council of regional and Group logistics managers.

For business air travel, we have established the means for data collection and the methodology for emissions calculation, based on the UK Department for Environment, Food and Rural Affairs and Department of Energy and Climate Change methodology. Data collection began in 2010, and the 2011 data are now included in our third party assurance process.

Energy and climate performance: Other GRI indicators

|

EN3 Direct energy use by ABB (Gigawatt-hours – GWh) |

| |||||||

|

Primary fuel |

2011+Baldora |

2011b |

2010 |

2009 | ||||

| ||||||||

|

Oil (11.63 MWh/ton) |

94 |

92 |

114 |

87 | ||||

|

Coal (7.56 MWh/ton) |

0 |

0 |

0 |

0 | ||||

|

Gas |

589 |

417 |

427 |

415 | ||||

|

Total direct energy |

683 |

509 |

542 |

502 | ||||

|

EN4 Indirect energy use: Consumption and losses at utilities (Gigawatt-hours – GWh) |

| |||||||||||||

|

Energy source |

2011+Baldora |

2011b |

2010 |

2009 | ||||||||||

| ||||||||||||||

|

District heat consumption |

195 |

195 |

223 |

259c | ||||||||||

|

District heat: Losses at utilities |

29 |

29 |

33 |

39 | ||||||||||

|

Electricity consumption |

1,621e |

1,447e |

1,335d |

1,321c | ||||||||||

|

Electricity: Losses at utilities |

2,239 |

1,999 |

1,844 |

1,824 | ||||||||||

|

Total indirect energy |

4,084 |

3,670 |

3,436 |

3,442 | ||||||||||

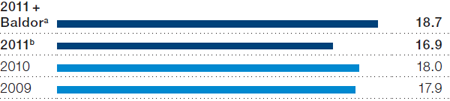

Megawatt-hours (MWh) per employee

a ABB and Baldor facilities included

b ABB operations only, not including Baldor facilities

Direct and indirecta energy use by type for 2011b

a Not including losses at utilities

b Data for ABB only, not including Baldor

|

EN16, EN17 Greenhouse gas emissions (kilotons CO2 equivalents) |

| |||||||||||

|

|

2011+Baldora |

2011b |

2010 |

2009 | ||||||||

| ||||||||||||

|

Scope 1 |

|

|

|

| ||||||||

|

CO2 from use of energy |

144 |

109 |

117 |

107 | ||||||||

|

SF6 |

263 |

263 |

247 |

263 | ||||||||

|

CO2 from transport by own fleet |

350c |

350c |

350c |

350c | ||||||||

|

Scope 2 |

|

|

|

| ||||||||

|

District heat consumption |

43 |

43 |

49 |

57 | ||||||||

|

District heat: Losses at utilities |

7 |

7 |

8 |

9 | ||||||||

|

Electricity consumption |

348 |

309 |

293 |

290 | ||||||||

|

Electricity: Losses at utilities |

480 |

427 |

405 |

400 | ||||||||

|

Scope 3 |

|

|

|

| ||||||||

|

Air travel |

N/A |

185 |

160d |

N/A | ||||||||