Reducing impacts

Our stakeholders have confirmed that ABB’s operational efficiency – optimizing the use of resources and minimizing waste – is of significant interest to them. Addressing these issues also contributes to our business success by reducing costs and risks, improving the work environment for our employees and helping to maintain our license to operate.

Reducing impacts where it’s most needed

Although our manufacturing processes do not consume significant amounts of water, ABB is nonetheless committed to reducing our impact on local water resources. In order to better understand the potential impacts, we have employed the World Business Council for Sustainable Development’s Global Water Tool to map our water use relative to the renewable water resource availability in the countries and watersheds where we operate.

We have taken this analysis one step further and developed an in-house water tool for mapping and analysis of water flows at our facilities. The tool was rolled out during 2012 in a program targeting our manufacturing facilities in water-scarce and extremely water-scarce watersheds1. These facilities, located in 15 countries across five continents, were required to systematically review water flows, analyze water-related opportunities and threats to their operations, and develop water action plans to minimize risks and to leverage opportunities.

The resulting action plans identified a wide range of opportunities to reduce impacts, including both behavioral and technical solutions. The most frequently described actions were the installation of aerators and low flow taps, identification of reuse opportunities for water from cooling systems and domestic uses, as well as awareness-raising and training programs. Many facilities have now installed flow meters to enable measurement of water use at key points and detection of leaks. This more detailed data helps to track performance improvement and to identify further improvement opportunities. Read more in our case study.

The program is already showing concrete results. Water use at facilities in water-scarce and extremely-scarce watersheds was reduced by 14 percent from 2011 to 2013. This delivers multiple “wins” – reducing water reduces both demand on a precious resource and the use of power to move water to and from our facilities – and it saves us money.

14% cut in water use in water-scarce areas since 2011

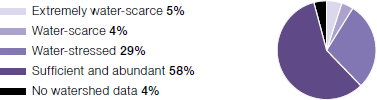

We have now also included Baldor and Thomas & Betts facilities in our mapping of ABB activities by watershed status. A total of 41 ABB sites are located in extremely water-scarce watersheds (of these, 6 are offices only) and 60 sites in water-scarce watersheds (of these, 13 are offices only). However, these sites account for less than 10 percent of ABB’s global water withdrawals.

We will continue to monitor and support the implementation and periodic update of the water action plans and track performance via our environmental reporting process. As part of our activities to integrate acquired companies, we will work to introduce the ABB Water Tool and develop improvement plans at the relevant facilities.

Water in our global operations

Looking at ABB’s global operations in 2013, nearly half of our water withdrawals (47 percent) were used for cooling processes, about a third used for domestic purposes such as sanitation, cooking or garden maintenance (32 percent) and the remainder for manufacturing processes (21 percent). None of our extractions caused significant changes to water sources during 2013.

Water withdrawal 2013 per watershed status

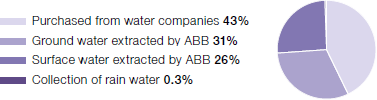

Sources of water withdrawals in 2013

Of those sites that use water for process purposes, more than 30 percent use closed-loop systems. Excluding cooling water returned to the source of extraction, the use of closed-loop processes and the reuse of water in other ways saved approximately 5.9 million tons of water in 2013. Without this recycling and reuse, ABB’s water withdrawals would have been more than 50 percent higher.

About half of our water discharge was to public sewers (48 percent), with almost 25 percent of that volume first processed at our own treatment plants. Another 45 percent was discharged to surface or ground water, with 75 percent of that volume pre-treated. The remainder was handled by hazardous waste water treatment companies.

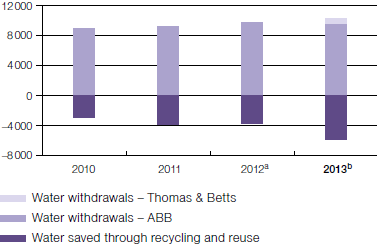

Water withdrawals and water reused/recycled (kilotons)

a Baldor facilities are included; Thomas & Betts not included.

b Baldor and Thomas & Betts facilities included.

Waste and recycling

ABB products contain mostly steel, copper, aluminum, oil and plastics. The majority of this material is reclaimable at the end of the product’s life and we enhance the ability to recycle by designing products that can be dismantled more easily and by providing users with recycling instructions.

Consequently, the main waste streams at ABB facilities are metal, oil and plastic, as well as wood and cardboard from packaging materials and paper from office activities. We aim to optimize material use, increase the share of waste that is reused or recycled and reduce the absolute amount of waste sent for final disposal.

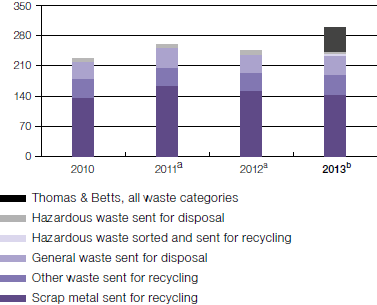

Compared with 2012, there was no significant change in the total volume of waste generated at ABB’s ongoing operations in 2013, despite increased business volumes and plant refurbishments and consolidation.

Considering all of our businesses, in 2013 ABB sent 81 percent of total waste for recycling, compared with 82 percent in 2012. However, the absolute volume of waste sent for final disposal increased, due to the first-time incorporation of newly acquired businesses in our 2013 results.

In-house recycling, mainly of packaging materials and thermoplastics, reduced the amount of waste by 3,900 tons. In total, we generated about 12,000 tons of hazardous waste in 2013, but sent almost 40 percent of that amount for recycling rather than disposal.

Waste and recycling (kilotons)

a Baldor facilities are included; Thomas & Betts not included.

b Baldor and Thomas & Betts facilities included. New category introduced – “Hazardous waste sorted and sent for recycling”. Previously included in “Hazardous waste sent for disposal”.

ABB operations undertake a wide range of waste reduction and recycling initiatives, bringing both environmental and cost benefits for the business. The nature of the improvement activities generally depends on the characteristics of the production processes and the local waste infrastructure. However, common themes emerge.

As a first step, many locations focus on awareness building and on ensuring processes are designed to support material efficiency and appropriate waste sorting for recycling. Process improvements can range from changing purchasing practices to encourage the supply of goods in bulk containers, thus reducing packaging waste, to improving inventory management of perishable goods, thus minimizing the disposal of expired materials. These good practices are also being implemented in many of our canteens where the focus is on reducing the supply of water in plastic bottles, better management of food waste and increased recycling.

During 2013, a number of our operations invested in novel processes to reduce or reuse waste. For example, a plant in the Czech Republic created a new type of compression mold to enable production of a component from recycled plastic. Our drives repair business in France implemented a new “biological fountain” to clean the electrical equipment. The new process uses micro-organisms rather than chemicals as cleaning agents, reducing hazardous waste generation by more than four tons in 2013.