Products and services

Contributing to a better world

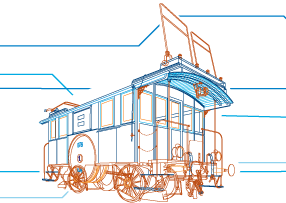

Many of the benefits of the modern world, from electricity at the touch of a switch to the consistent high quality of industrial goods, are made possible by technology that was pioneered, improved and adapted by ABB over more than a century of innovation.

Technological innovation remains a cornerstone of ABB’s competitiveness and a key driver of profitable organic growth. In 2015, we invested $1.4 billion, or 4 percent of revenues, in research and development by our 8,200 technologists. In this way, we create and support a comprehensive range of products, systems and services that increase energy efficiency, reliability and productivity for our industrial, utility, and transport and infrastructure customers.

It is through this comprehensive offering that ABB makes a key contribution to a ‘better world.’ Our energy efficient and renewable energy portfolio directly contributes to the reduction of greenhouse gas emissions, while our technologies also facilitate access to reliable, modern energy, contributing to economic growth and improved quality of life for communities.

As part of our sustainability objectives, ABB is committed to increase revenue from our portfolio of energy efficiency-related products, systems and services by 20 percent by 2020, from a 2013 baseline. In 2015, these portfolio revenues declined slightly to 50 percent of total sales (51 percent in 2014), against a background of lower full-year earnings.

of electric power saved by our variable speed drives

The criteria defining the ABB energy efficiency portfolio were developed in 2011, based on current technology standards and ABB’s business scope. Given the subsequent technology improvements, significant organic and inorganic changes to ABB’s business portfolio, and the launch of our Next Level strategy in 2014, we decided to review the basis of the energy efficiency portfolio during 2015 to ensure relevance in the coming years.

After extensive consultation throughout our business and with the help of external reviewers, we developed an expanded “eco-efficiency” portfolio that now includes energy efficiency, renewable energy and resource efficiency criteria. To improve transparency and consistency, we have established more stringent selection criteria and detailed guidelines, and have defined a regular portfolio review process. We expect to finalize and roll out this strengthened methodology during 2016. Read more in our Case study

Research and development

Historically, the core of ABB’s innovation success has been the close proximity to customers that has allowed us to understand their needs, as well as the collaboration between the Corporate Research organization that serves the entire company and the research and development (R&D) teams in the businesses. These partnerships have provided the foundation for many of our pioneering technologies and are driving the transformation of power and automation.

With research centers in China, Germany, India, Poland, Sweden, Switzerland and the US, we are well positioned to access local talent, evaluate ideas emerging from academia all over the world, test the commercial viability of new products and solutions and, most critically, share technology to make it accessible throughout the entire group.

ABB follows a Group-wide approach to product and technology development, known as the ABB Gate Model. Sustainability aspects are built into this process, including a handbook to guide consideration of health, safety and environmental (HSE) aspects, an HSE Checklist and material selection guidelines. Read more about our design processes in the Resource efficiency chapter.

Internet of Things, Services and People

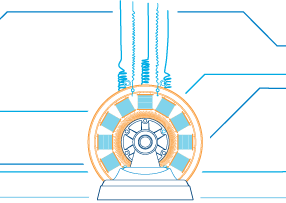

One core area of R&D for ABB is the Internet of Things, Services and People (IoTSP) that enables web-based automation and control solutions to improve productivity and quality. For more than a decade we have been working to develop and enhance process control systems, communications solutions, sensors and software for the IoTSP.

The technologies that enable ABB’s IoTSP strategy also allow the development of entirely new service offerings. To support this development, service requirements are now included in ABB’s standard R&D process, and product developers are required to work with our service organization to ensure the required service capabilities and resources are available at product launch.

One of the recent successes of our service R&D approach is the development of several smartphone applications to ease and enhance the use of ABB drives. These tools provide an easy-to-use approach for the commissioning, servicing and use of ABB drives. As well as reducing cost and complexity for our customers, the wireless connections also mean that engineers don’t need to enter hazardous or difficult-to-reach work areas to access information needed to help them commission and tune a new drive.

ABB has also developed ServicePort™, a secure, remote-enabled service delivery platform that allows customers and ABB experts to view, scan and track key performance indicators to ensure maximum performance of equipment and processes. The platform helps users make better informed decisions resulting in higher operational efficiency while reducing raw material use and energy costs.

As opportunities of the IoTSP evolve, so too does the need to be protected from cybersecurity threats. For ABB, protection of the IoTSP’s interwoven systems of information technology and operational technology is central to our strategy and we work with customers to create a defense-in-depth approach where multiple security layers detect and deter threats in all of our products, systems and services.

The technical possibilities and business advantages that accompany the IoTSP rely on a safe, reliable supply of electricity. With increasing generation from renewable sources, often in remote locations, utilities face the challenge to transmit large amounts of power over long distances, efficiently and reliably, and to integrate this more dynamic and intermittent power into the grid. High-voltage direct current (HVDC) is the technology of choice for the efficient transmission of electricity over long distances and to create cross-border interconnections to strengthen grids. ABB pioneered HVDC technology over 60 years ago and accounts for about half of the global installed capacity.

ABB is also pioneering an innovative method to allow greater access to affordable electricity. Small communities often have no access to electricity, not because they are remote from the grid, but due to the cost of installing the substation that is needed to tap the high-voltage transmission lines. ABB has now developed a micro-substation that enables local power supply with a small capital outlay and low maintenance requirements.

We are also actively driving our technology development by working with leading institutions. Our investments in research initiatives, fellowships and strategic partnerships with over 70 universities and research institutions around the world continue to enhance the ABB portfolio and lead to international and cross-industrial cooperation in almost every ABB business.

Start-ups and partnerships

The pace of innovation required today is increasing due to societal changes and environmental concerns, as well as to the rapid development of technologies such as those related to the IoTSP. For these reasons, we are also pursuing new ways of driving innovation.

ABB Technology Ventures (ATV) was set up as the strategic venture capital investment arm of ABB five years ago to invest in high-potential industrial technology and energy companies aligned with our mission.

The unit’s most recent investments are in businesses with disruptive technology in areas such as artificial intelligence and 3-D printing. ATV has acquired a stake in Vicarious, for example, which is building a unified algorithmic architecture that will take us closer to achieve human-level intelligence in vision, language and motor control, and could be applied to select applications in ABB’s portfolio.

We are also establishing partnerships with strong global or local players who can help us penetrate new markets and develop new offerings. A recent example is the electric vehicle fast-charging services platform launched with Microsoft, which combines our charging stations with Microsoft’s cloud-based services. The collaboration will take advantage of machine learning and predictive analytic capabilities to drive future innovations.

ABB has also established a global commercial alliance with Samsung SDI to develop and market modular and scalable microgrid solutions, utilizing lithium-ion batteries for energy storage. Effective microgrid solutions will promote and broaden access to electricity in emerging markets and remote areas while providing power reliability, resilience and security to developed markets.

Shaping the future

With roots in power and automation that go back to the 19th century, ABB innovations have helped to build the world we know today and are helping to fashion the world we will live in tomorrow.