Industry

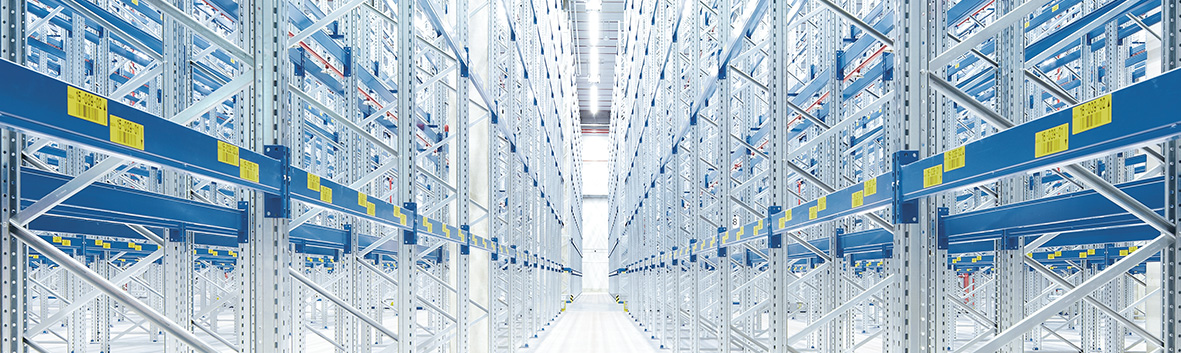

ABB technologies are key enablers of industrial productivity, increasing the output, quality, variety and affordability of goods, and helping to raise living standards around the world. They power manufacturing and processing plants, monitor and manage the processes to maximize efficiency, ensure people, process and product safety, and drive key equipment.

Energy efficiency and productivity are the hallmarks of ABB’s offerings for industry. Our energy efficient products, systems and services reduce consumption and therefore electricity bills and carbon emissions, while our automation systems increase productivity, quality and efficiency, and keep workplaces safe.

Productivity

Thanks to its long history of developing automation solutions for industry, ABB is today the global leader in distributed control systems, with more than 20 percent market share*. Our systems measure, analyze, diagnose, and provide full control of industrial plants in industries from chemicals, pulp and paper, mining, minerals processing (e.g., cement making), to pharmaceuticals and food and beverage.

Energy efficient

Complementing our portfolio of control systems are our energy efficient motors and drives, where we are also global market leader. Last year, our installed base of drives saved about 445 terawatt hours (TWh) in electricity, equivalent to the annual power consumption of 110 million European households. Only a small proportion of the world’s electric motors, which account for about 70 percent of industrial electricity consumption, are able to efficiently adjust their power use to match the required demand. This leaves significant room for continued market expansion, which is further supported by increasing minimum energy performance standards in many countries and industries.

Redefining robotics

As the company that pioneered the world’s first electrically powered industrial robot in 1974, ABB supplies robots for industries as diverse as automotive, packaging and palletizing, and consumer electronics. Now we are again redefining robotics with YuMi, an innovative dual-arm collaborative robot. YuMi is designed for a new era of automation; for example, in small parts assembly, where people and robots safely work alongside each other on the same tasks.

Service

Tying together ABB’s portfolio of automated systems is our comprehensive range of service offerings. Our life-cycle services ensure the health, reliability and continual evolution of installed equipment, while our experts can be called on to help customers reduce energy consumption and improve process efficiency and reliability. ABB also offers a host of remote monitoring and predictive maintenance services that can alert and dispatch service experts to resolve potential issues before a shutdown occurs.

* According to leading technology research and advisory firm ARC Advisory Group