Resource-efficient and environmentally sound solutions in Electrification

In ABB’s Electrification Business Area, we recognize that new solutions are needed to manage the pressures being placed on our environment. Our aim is to help make a safe, smart and sustainable world possible with technologies that reduce energy consumption, eliminate emissions in industry, infrastructure and transport, and improve quality of life.

Mission to Zero

We are committed to showing the world that the energy transition can be achieved sustainably through our digital energy-management solutions. The necessary steps are outlined in “Mission to Zero,” the carbon-neutral and energy self-sufficient blueprint we introduced in 2019 for industry, homes and cities. To demonstrate our confidence, we are using our own facilities as test beds for our comprehensive zero-emission concept.

ABB’s flagship Busch-Jaeger site in Lüdenscheid, Germany, is our first carbon-neutral and energy-self-sufficient production site in the world. The ABB technology it relies on, which has our scalable energy management system OPTIMAX® at its core, generates enough climate-neutral solar power to cover 100 percent of the factory’s power requirements on sunny days and has reduced the site’s CO2e emissions by some 680 tons per year. For Lüdenscheid, we developed a zero-emission solution that is scalable, flexible and suitable for a wide range of applications. We are now rolling out our Mission to Zero concept at other Electrification sites and will share our learnings with customers and key stakeholders.

Solutions to reduce power losses

According to the International Energy Agency (IEA), the hypothetical implementation of all of the currently available energy-efficient technologies would deliver 40 percent of the emissions reductions needed to meet the requirements of the Paris Agreement. ABB is a leader in the development of energy-efficient technologies that enable the achievement of global climate targets.

Energy-efficient solutions for data centers

By 2030, hyperscale data centers are projected to account for 15 to 30 percent of total electricity demand in some smaller countries. Our MegaFlex DPA™ uninterruptible power supply (UPS) is designed for exactly this kind of challenge. Compact, flexible, safe and easy to install, it enables data center operators to track energy consumption precisely. Its default operating mode enables efficiency of up to 97.4 percent, with an ECO option to attain 99 percent efficiency. This solution is designed to work with the rest of ABB’s power infrastructure products to ensure a continuous flow of clean power to a data center. MegaFlex DPA was awarded the Solar Impulse Foundation’s “Efficient Solution” label, an important recognition from an external agency of our work to reduce power losses.

Energy-efficient solutions for switchgear

Watch the video at https://youtu.be/o0u8CDYXWsU

Industry is under constant pressure to reduce injuries, energy consumption and overall costs. To meet these needs, we developed the first real innovation in low-voltage switchgear since the 1980s. NeoGear’s bus plate system is fully protected against arc ignition, so it is substantially safer than any previous switchgear system. Furthermore, NeoGear needs less copper, emits 20 percent less heat, requires less energy for cooling, and takes up to 25 percent less space. Underpinned by our ABB Ability™ platform for better energy management, condition monitoring and predictive maintenance, it can reduce operational costs by up to 30 percent. NeoGear is superior to any other switchgear solution, and we are confident it will ultimately replace conventional switchgear almost entirely.

Solutions to optimize energy use

Growing urbanization and digitalization and concerns about climate change are driving the need to think beyond energy-saving measures and shift towards energy optimization. At ABB Electrification, we are facing this challenge head on, helping our customers adapt and thrive with our advanced technologies.

Energy optimization solutions for companies

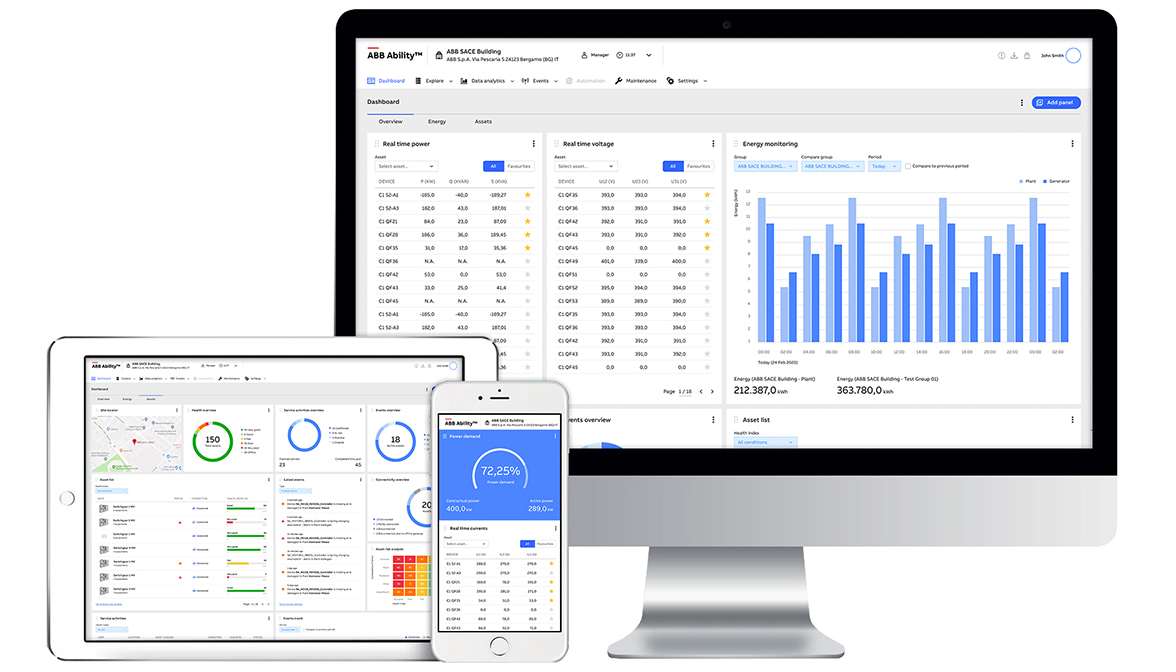

It has become essential for companies to reduce energy costs and shrink their carbon footprints as their stakeholders become increasingly concerned about sustainability. To meet this need, we developed a suite of ABB Ability™ plant- and enterprise-level applications, called ABB Ability™ Energy Manager. This scalable solution can pull together real-time and historical data from energy providers and a company’s commercial and industrial systems to help customers optimize their energy usage, saving up to 30 percent on operational costs. ABB Ability™ Energy Manager enables reduced energy consumption by comparing actual consumption against targets and identifying, in real time, the areas where improvement is required. It can also help companies optimize their energy consumption with planning and scheduling applications that let them get the best pricing for the energy they require.

Energy-optimization solutions for buildings

Buildings consume more than 30 percent of the world’s energy and generate nearly 40 percent of annual global GHG emissions. ABB Electrification has developed a wide range of smart solutions for buildings that can significantly reduce their total carbon footprint.

Smart buildings are not new. For decades, architects and developers have been installing separate systems to control lighting, heating and ventilation, among others. What is new, however, is the addition of web-based platforms, such as our range of ABB Ability™ building automation solutions. Our smart building technologies seamlessly integrate all of these systems, providing building managers with a single view of how efficiently a building is operating, so they can make better decisions. And with the right systems, buildings today can make autonomous decisions to adjust lighting, heating, air conditioning and other systems to reflect the time of day, outside weather or any other variable. When fully implemented, our building automation solutions typically deliver up to a 30 percent reduction in energy costs for heating, lighting and appliances.

Emission-free alternatives

The world needs to adopt approaches and technologies that can reduce global GHG emissions. In ABB Electrification, we are committed to providing the world with emission-free solutions that will enable future generations to pursue economic growth without contributing further to climate change.

Emission-free mobility

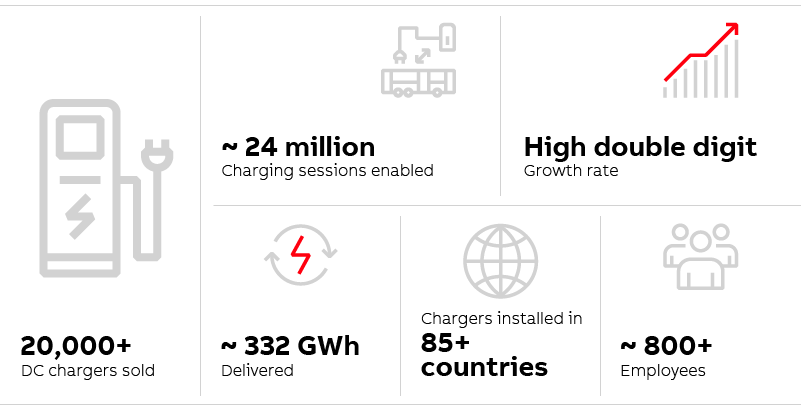

Active across the e-mobility value chain, ABB is the world leader in fast-charging solutions, which are increasingly in demand as the world works to shift away from polluting internal combustion engines. We have sold more than 400,000 electric vehicle chargers across more than 85 markets, including those sold through Chargedot, our subsidiary in China. Our DC fast chargers run on the ABB Ability™ Connected Services Platform, which employs Microsoft’s Azure cloud services to enhance uptime, scalability and operational efficiencies, as well as to provide real-time remote support services. ABB provides not only EV charging stations, but also critical EV charging infrastructure components, such as substations, energy storage systems and eco-friendly switchgear. These technologies are designed so that EV charging stations, once installed, will be both future-proof and scalable.

For mass transit, ABB offers solutions for the electrification of buses. And for the electrification of railways, we support sustainable mobility with power and automation technologies for customers ranging from train builders to rail operators. We design, engineer and commission solutions to deliver safe, reliable and cost-effective rail freight and passenger transportation solutions. Our product offering includes traction transformers, motors and converters that move vehicles quickly and reliably. It also encompasses leading integrated and collaborative digital solutions with ABB Ability™.

Emission-free solutions for the power industry

The production and consumption of energy is responsible for roughly two-thirds of global GHG emissions. To enable our power industry customers to reduce their emissions, we have developed AirPlus™, a groundbreaking eco-efficient gas mixture that will enable electric utilities to avoid using sulfur hexafluoride (SF6) in gas-insulated switchgear (GIS) applications. SF6 is one of the most potent GHGs – 23,000 times more damaging to the climate than CO2, with an atmospheric lifetime of 3,200 years, according to the Intergovernmental Panel on Climate Change. While SF6 has been used as a reliable insulation gas in switchgear for over 50 years, AirPlus is equally reliable – with almost zero global-warming impact and no compromise to the footprint or performance of the switchgear.

While our medium-voltage (MV) GIS uses AirPlus, we have also developed another solution, Dry Air, a natural gas replacement for SF6 that is suitable for 12kV applications. Both of these SF6 -free technologies allow our switchgear to be operated at a lower tank pressure.

In 2020, we launched our latest primary GIS, PrimeGear ZX0. Designed for use in MV networks, it builds on ABB’s digital monitoring and diagnostic solutions and incorporates our proven SF6-free switchgear technology. PrimeGear ZX0 is the world’s first switchgear designed to enable customers to transition easily from SF6 to our SF6-free alternative at any point in the switchgear’s lifetime.

Lessons learned

Over the past seven years of ABB’s sustainability reporting cycle, we have increasingly learned to appreciate the value of collaborating across functions within our Group, while working closely with customers, suppliers, startups and academia to achieve ABB’s sustainability objectives.

We have also determined that small actions, like changing the material we use to manufacture a simple product or part, can have a tremendous impact on the sustainability of our business in mature markets. Similarly, we have recognized the importance of understanding the true drivers of our CO2 footprint within the product lifecycle.

Based on our experiences over this period, we have also learned that we can make our operations more circular by collaborating with suppliers to find ways to achieve the “closed-loop” recycling of plastic waste from our own manufacturing processes. At the same time, we have determined that we can improve ABB’s Scope 3 emissions and the carbon footprint of our solutions by working with our suppliers to reduce their carbon footprints and by focusing on low-carbon logistics.