Resource-efficient and environmentally sound solutions in Process Automation

In ABB’s Process Automation Business Area, we are dedicated to equipping our customers in the process and maritime industries with products, systems and solutions that make their operations safer, smarter and more sustainable. Our offerings are based on ABB’s leading technologies – such as distributed control systems, marine propulsion, turbocharging, measurement and analytics – as well as deep domain expertise and industry-specific products. Each solution is supported by a range of remote services for the duration of the asset’s lifetime.

Reducing emissions through better marine technologies

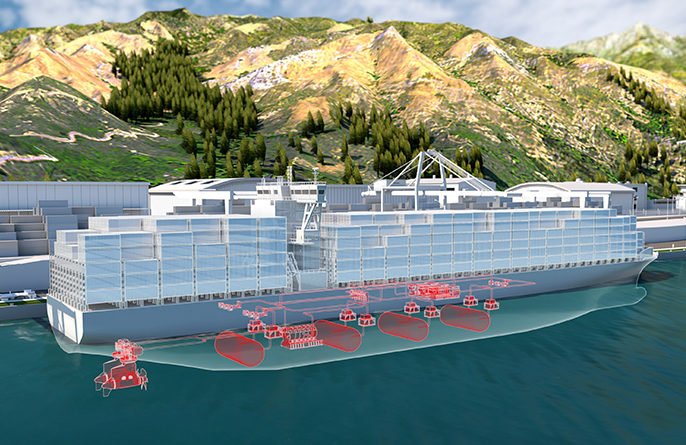

Automation, electrification and digitalization are central to the energy transformation in the process and maritime industries. ABB plays a major part in reducing the environmental impact of the shipping industry with leading technologies that include Azipod® electric propulsion, the latest generation of turbochargers continuous emissions monitoring and the electrification of ferry services.

Azipod® is a gearless, steerable propulsion system that deploys an electric motor, placed in a submerged pod extending outside a ship’s hull. Azipod® units rotate 360 degrees to increase maneuverability and operating efficiency, with a proven ability to cut fuel consumption by up to 20 percent compared to traditional shaftline propulsion systems. In addition to hardware, we provide fuel-saving software solutions to the marine industry. ABB Ability™ Tekomar XPERT diagnostic software enables large-vessel operators to reduce fuel consumption and manage their fleets more efficiently, collecting data from a wide range of sensors and other indicators in and around a ship’s engines and recommending optimal settings for engine operation.

In January 2020, emission limits in International Maritime Organization (IMO) regulations became effective worldwide. To help customers comply, ABB expanded its extensive continuous emission monitoring portfolio with a marine-specific system called CEMcaptain. Our intention is that its measurement and digital capabilities increase on-board safety, provide process optimization, and substantially reduce ownership costs by requiring less maintenance.

We also offer zero-emission technology to the marine industry, and recently equipped a new generation of fully electric ferries that replaced the diesel vessels on the iconic Maid of the Mist tour at Niagara Falls. The two new 28-meter catamaran ferries are powered solely by high-capacity battery packs, making them the first fully electric vessels ever built in the United States.

Our solutions are also used in large, shaftline propulsion ships to increase engine efficiency. Our turbocharging portfolio comprises single- and two-stage turbocharging solutions. The latter is capable of producing high pressures at efficiencies of 75 percent or more, reducing fuel consumption, extending service intervals, and helping customers reduce environmental impact and comply with IMO regulations.

Improving environmental performance with smarter industrial processes

ABB’s automated control solutions are designed to increase output while reducing energy usage and waste of raw materials. Our suite of ABB Ability™ solutions and services uses sensors, network connectivity and data analytics to provide a real-time view into operations, enabling predictive maintenance, improved safety and better environmental performance.

This includes our first cloud application for original equipment manufacturers (OEMs), the ABB Ability™ Asset Performance Monitor. Launched in 2020, it collects data on production rates, energy consumption and temperature, and provides a continuous overview of an OEM’s entire installed base, enabling more informed business decisions. Data is displayed on a digital dashboard, giving OEMs the necessary insights to initiate machine upgrades and advanced services. State-of-the-art security standards and transfer protocols ensure data integrity. This is just one of the many flexible, scalable and secure solutions that we offer to facilitate the shift to smart industrial processes. Digitalizing production processes increases system reliability and throughput, reduces raw material and energy use, and improves product quality.

With these goals in mind, ABB Process Automation has been deeply involved in laying the groundwork for an all-electric mine concept, developing several solutions focused specifically on the electrification, automation and digitalization of mines. One example is the ABB Ability™ Ventilation Optimizer, a modular system that maximizes the efficiency of mining ventilation systems. While maintaining proper air quality in a mine, this solution delivers energy savings of up to 50 percent per year.

Driving the energy transition

ABB Process Automation is developing technologies to facilitate the energy transition for our industrial customers. As a member of the European Clean Hydrogen Alliance, ABB is helping to scale up the hydrogen value chain across Europe. Hydrogen has several uses, from storing renewable energy to fueling heavy transport, and as a feedstock in energy-intensive processes. Most importantly, hydrogen only emits water and heat when used as a fuel, releasing no carbon. In fact, if hydrogen is produced from renewable sources, the whole hydrogen value chain is carbon-free. Hydrogen thereby serves as an excellent complement to electricity and offers a solution to decarbonizing industrial processes and economic sectors where reducing carbon emissions is both urgent and difficult to achieve. Hydrogen is crucial to achieving the objectives of the European Green Deal and ensuring Europe’s transition to clean energy.

To help hasten the energy transition, we are working with Hydrogen Optimized on the development of large-scale, environmentally friendly hydrogen production systems. In 2020, the two companies signed an MOU to make green hydrogen a financially viable option for our customers. We have also been cooperating with ABB’s Electrification Business Area on the transformation of ABB’s Busch-Jaeger production site in Lüdenscheid, Germany, into an example of how the energy transition can be successfully accomplished with currently available technology. We are exploring the possibility of using hydrogen as a clean source of energy at the site, which already has a solar plant that generates enough power on sunny days to meet all of its power requirements.

In the Asia–Pacific region, ABB is supporting the Hydrogen Energy Supply Chain (HESC) project. HESC aims to safely and efficiently produce hydrogen in Australia and transport it to Japan, in one of the world’s first efforts to commercialize hydrogen liquefication and transportation. The project is poised to position Australia as a leader in hydrogen production, and with the world’s fifth-largest energy consumption, yet low fossil fuel resources, Japan considers hydrogen key to meeting future energy requirements. ABB won orders in both countries: an electrification and instrumentation contract in Australia, and an automation contract in Japan from Kawasaki Heavy Industries.

Conserving resources through advanced digital solutions

ABB Process Automation is a key provider of technologies and solutions that help conserve valuable resources such as clean water and natural gas.

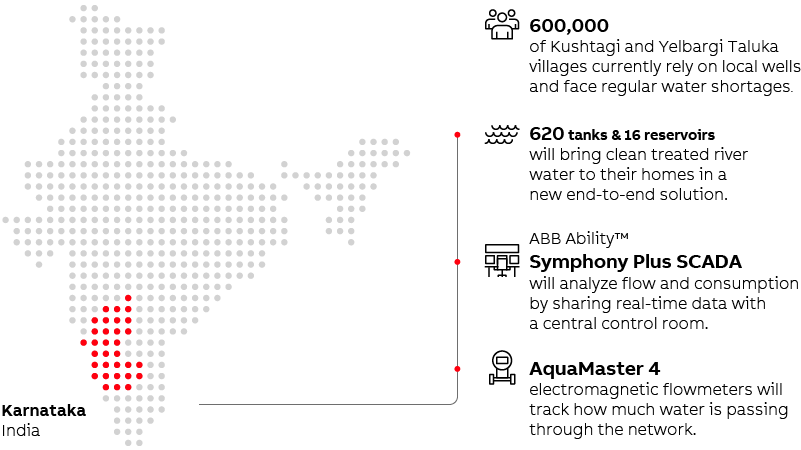

We designed our ABB Ability™ Symphony® Plus SCADA to maximize the reliability and availability of water plants and networks. The control solution deploys integrated information management, the integration of equipment, and process optimization based on data from an entire water network. ABB’s AquaMaster 4 electromagnetic flowmeters, which can run on battery power, provide reliability even in low flow conditions and in areas where most mechanical flowmeters would fail. ABB flowmeters are used across India in urban, semi-urban and rural settings. For example, in the Koppal district, a drought-prone region in southwestern India, we provided end-to-end digital water management solutions to help the local water authority not only track, measure and optimize water use, but also pump and distribute treated river water to homes. Equipped with ABB Ability™ Symphony® Plus SCADA and ABB’s AquaMaster 4 flowmeters, the district is effectively monitoring water flow, managing leaks and delivering overall productivity improvements to its widely dispersed network.

ABB supports India’s Koppal district to ease water shortages with digital water management solutions

We also offer solutions to rapidly detect and locate gas leaks, which is not only critical to the security and resilience of gas infrastructure, but also to reducing GHG emissions. Our complete Gas Leak Detection Platform makes it possible to find leaks in any natural gas infrastructure – upstream, midstream, downstream or utilities – with far higher reliability and speed than ever before by combining sophisticated measurement technologies with advanced data analytics. The innovative platform uses advanced laser absorption technology to provide fast, sensitive measurements that distinguish between naturally released methane and gases leaking from a buried pipe or other potentially dangerous source.

In Western Australia, our gas measurement technologies will soon also be used to help convert waste into sustainable energy. In 2020, three ABB ACF5000 analyzers were selected to monitor, measure and analyze the composition of exhaust gases at the new, large-scale East Rockingham Waste-to-Energy facility near Perth. ABB Ability™ Condition Monitoring for measurement devices will enable us to monitor these analyzers remotely throughout their lifecycle.

Lessons learned

Over the past decade, the oil & gas, mining and marine sectors have dramatically changed, and our business has adapted to serve their needs. Increasingly, our customers are turning to ABB to help them save energy, increase safety, reduce costs and achieve their own, wider sustainability goals. Because our customers face increasing regulatory obligations across all of their markets, an investment in automation technologies that improves environmental performance is frequently viewed not only as the right thing to do, but also as a sound business decision that can drive overall safety, efficiency and productivity.

Based on our experiences during the previous sustainability reporting cycle, we have learned that we need to elevate the profile of our contributions to sustainability. While our customers have always known and recognized ABB for the safety and efficiency of our portfolio, we see an opportunity to emphasize how our solutions can contribute to reducing their environmental footprints. This will involve educating our salesforce, raising awareness of our contributions among all of our employees, and building a stronger understanding of our offering in the market.