Climate action Cutting emissions across our value chain

Over the past seven years, ABB has focused on reducing its carbon footprint

Our work to reduce ABB’s carbon footprint during the current reporting cycle has been highly successful. This achievement forms the foundation for our ongoing ambition to make even greater contributions to the global effort to realize the climate goals enshrined in the Paris Agreement, which is fundamental to limiting global warming. That is why, despite achieving our climate action target a year ahead of schedule, in 2020 we pushed to achieve further reductions in greenhouse gas (GHG) emissions in ABB’s operations.

Target status

ABB’s 2020 target for climate action was to reduce its GHG emissions by 40 percent from a 2013 baseline. In 2020, ABB’s total GHG emissions (Scope 1 and 2) amounted to 561 kilotons. To measure our progress, we have re-baselined our target by removing the contribution from our divested Power Grids business to the 2013 baseline. We have also excluded the emissions of the 39 new sites added in 2019, for which no 2013 baseline data exists. This shows we have achieved a 58 percent reduction from 2013. Our progress to date is mainly attributable to an increased proportion of green electricity (+27 percent since 2019) and improved methodology for monitoring emissions from our vehicle fleet.

Total GHG emissions (Scope 1 and 2) and GHG intensity

* PG not included for 2020

While it is critical to continue reducing ABB’s own GHG emissions, our leading technologies represent ABB’s main contribution to the global effort to mitigate climate change. Many of ABB’s products, services and solutions directly address the causes of climate change by facilitating increased energy efficiency, the integration of renewables into the energy mix, and the conservation of natural resources.

Minimizing our own carbon footprint

Within our own operations, our focus over the past seven years has primarily been on reducing GHG emissions from fossil energy and transportation, as well as from the handling of sulfur hexafluoride gas (SF6). In addition to these efforts, in 2020 all of our Business Areas and divisions worked to assess potential measures to cut their emissions in preparation for the ambitious new GHG targets in ABB’s 2030 sustainability strategy. A corporate-led climate-change program supported these assessments in 2020; during this time we built and sometimes transferred expertise to the divisions because, in line with ABB’s new operating model, our divisions are now fully accountable for their own GHG performance. The seminars and focused discussions we held with our 20 divisions were notably granular, addressing specific issues at our most important sites and suggesting potential improvement strategies.

In several European countries, all of our electricity is supplied from renewable sources. In 2020, 320 GWh, or 32 percent, of all the electricity used by ABB, was either purchased as certified green electricity or generated by our own solar power plants. These results represent an increase of 9 percentage points from 2019.

In 2019, our Motion Business Area launched a program to ensure it buys 100 percent green electricity well before 2025. In 2020, Motion made significant progress towards its goal, working to procure 100 percent green electricity for its production facilities in Finland and for all of its operations in Estonia and Switzerland. Through this effort and the continuous improvement of energy efficiency at its facilities, Motion slashed its GHG emissions by 64 percent from its 2013 baseline.

We continue to install on-site photovoltaic (PV) power plants at our facilities. As a result of our progress this year, ABB’s production of solar power for its own use increased by 36 percent in 2020. For example, Motion’s variable speed drives factory in Beijing is now listed as a national “green factory” by China’s Ministry of Industry and Information Technology. This listing recognizes ABB’s commitment to sustainability through the use of innovative processes to achieve low-carbon, energy-efficient manufacturing. The solar PV system on the factory’s roof generated more than 94 megawatt-hours in 2020. ABB’s own drives and high efficiency motors are also incorporated into the site’s heating, ventilation and air conditioning (HVAC) system, constant pressure water supply system and air compressors, reducing power usage by at least 50 percent. Waste heat from the motor test room is used to heat the factory in winter.

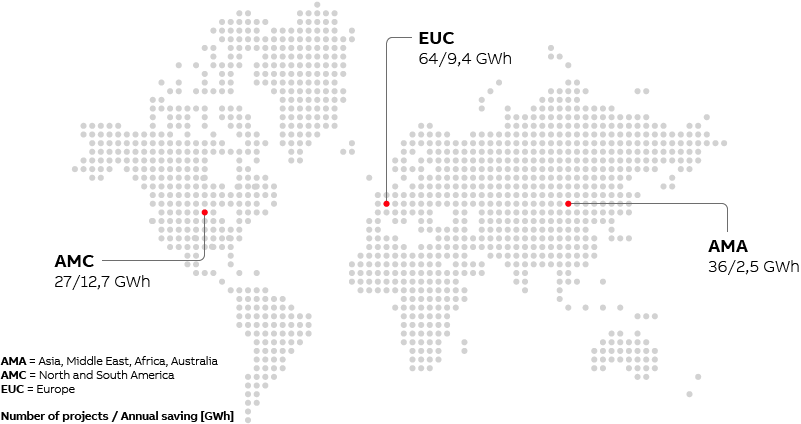

At present, there are more than 120 energy-efficiency projects underway at ABB sites around the world. We anticipate that these projects will reduce our annual energy consumption by more than 24 GWh, saving more than $3.5 million in energy costs each year.

Projects underway to increase energy efficiency

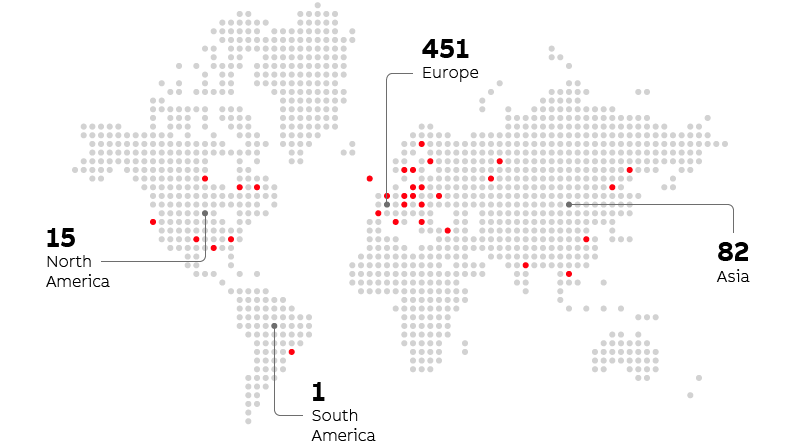

We continue to install EV-charging infrastructure at our sites. In 2020, the number of ABB sites equipped with EV-charging infrastructure increased to 24 percent, up from 17 percent in 2019. Out of 487 ABB sites in 39 countries, 115 sites in 25 countries are equipped with at least one EV-charging station; a total of 545 EV chargers have been installed to date. These figures include our work to prepare for the launch of ABB’s new e-fleet program, which will gradually introduce fully electric vehicles for our sales fleet and as benefit vehicles. This program will be kicked off in Germany in the first half of 2021.

Number of EV chargers at ABB sites

Also in 2020, the ABB Real Estate function’s energy savings program reaped a total of $8.1 million in savings between 2018 and 2020 from 174 completed, ongoing and planned energy-saving projects in ABB buildings; these projects enable us to cut our greenhouse gas emissions by 19.5 kilotons per year.

ABB Real Estate also works with our integrated facility management (IFM) suppliers to reduce the consumption of energy at all ABB IFM sites around the world. In 2020, we introduced an effective new tool called Rapid Energy Review, which enables us to quickly identify opportunities to save energy at ABB sites. With the help of energy specialists from our ABB IFM suppliers, we can then implement measures that are customized to each ABB site. Through this new, targeted approach we can reduce on-site energy consumption by as much as 5 percent. The energy-saving measures we take typically pay for themselves in one year or less. They also qualify us to receive an ISO 50001 company-level certification, which is awarded to companies that deploy an energy management system for the primary purpose of using energy more efficiently.

Our strong focus on climate change and on reducing our customers’ GHG emissions is reflected in the steadily improving scores we have received from the Carbon Disclosure Project. In prior years, ABB consistently received a grade of “C,” before receiving a “B” in 2019. We are very proud that in 2020 our focus and dedication was recognized with an “A-.”

Reducing the impact of our supply chain

This past year, for the first time, we conducted an evaluation of all relevant categories of Scope 3 emissions.

Since our last sustainability reporting cycle began in 2013, we have increasingly engaged with our suppliers on sustainability performance. In 2019, our expanded assessment of emissions in our supply chain showed that our upstream Scope 3 emissions are roughly six times larger than our own Scope 1 and Scope 2 emissions, offering a clear opportunity for emission reductions.

Accordingly, we took action in 2020 to help our suppliers reduce the climate impact of their operations. The Supplier Sustainability Rating program, created by ABB's Smart Power (ELSP) division in 2019, is a good example of our proactive approach to cutting ABB’s upstream Scope 3 emissions and should have an impact from 2021. Aimed at improving the carbon footprint of ELSP’s suppliers and turning their attention to circular economy principles, this program – among other, similar division-led initiatives – enabled us to have more substantive conversations with our high-impact suppliers on climate action and related topics.

Engaging customers on climate change

Our comprehensive Scope 3 assessments also clearly show that the use of sold products (category 11) represents the category that has by far the most impact on our total Scope 3 emissions. This highlights the importance to systematically engage and cooperate with our customers on the topic of climate change. Every day, we work to show them how our technologies can reduce their GHG emissions and energy costs. Many of our customers have a larger impact on the environment than we do, and our technologies can help them achieve their environmental goals. In particular, ABB specializes in providing technologies that enable utilities, industry and transport & infrastructure customers to deploy clean energy and improve energy efficiency while extending the lifecycles of their equipment and reducing waste. Our leading technologies are the reason why our four Business Areas are partners of choice for the efficient electrification of consumption points, robotics, intelligent motion solutions and process automation.

Lessons learned

In our previous sustainability reporting cycle, which began in 2013, we set a single “energy efficiency target”, which combined energy and emissions reductions as well as cost savings. Later, we revised this target to focus on greenhouse gas emissions only to be more in line with stakeholder expectations.

ABB has long been recognized for its leading technologies that help to reduce energy consumption and emissions of industries, transport and infrastructure. Our stakeholders appreciate that sustainability is a key part of our company Purpose and the value that we create.

By setting targets in line with our Purpose, we balance the needs of society, the environment and the economy, leading to a healthier and more prosperous future.