Target: By 2030, we will support our customers in reducing their annual GHG emissions by at least 100 megatons

We are aiming to enable our customers to reduce their annual GHG emissions by an amount equivalent to that generated by 30 million internal combustion cars. These indirect, downstream GHG emissions represent by far ABB’s largest potential impact on climate change.

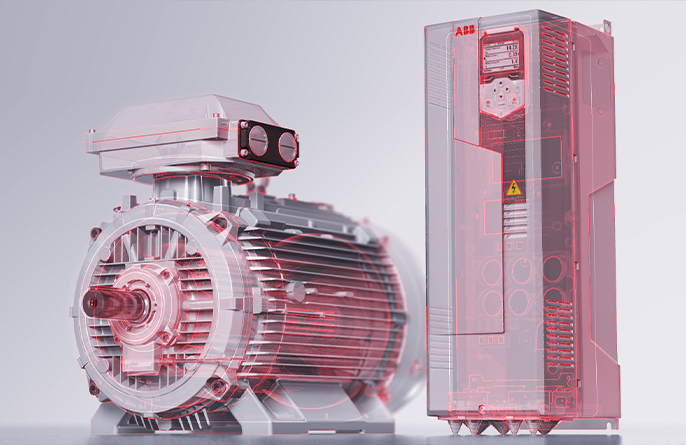

ABB’s Motion Business Area enables its customers to reduce their carbon emissions with a complete range of high-efficiency motors and drives. Found in a broad range of applications in industry and buildings, electric motors account for 45 percent of the world’s consumption of electricity, meaning that even small efficiency improvements offer the potential for huge energy savings.

In Switzerland in 2021, Model Group, a manufacturer of paper packaging, deployed energy-efficient motors and drives from ABB to upgrade its paper machines. Papermaking is an energy-intensive process, and by replacing 36 motors and drives in its factory with new, IE4 super-premium-efficiency models and multidrives, Model Group has reduced its energy consumption by nearly 900,000 kWh per year – equivalent to the power consumption of about 200 single-family homes.

ABB Motion’s work with Yara, a mineral fertilizer producer in Norway, illustrates another way we are helping customers save energy. Yara has begun to refit its largest production site with high-efficiency motors and drives from ABB; it has upgraded roughly 1,000 of the facility’s motors so far. In the project’s next phase, another 2,500 motors will be replaced with ultra-premium-efficiency IE5 SynRM motors and drives. The annual power savings at the company’s site in Porsgrunn are expected to be on the order of 32 to 40 GWh, resulting in an annual CO2 emissions reduction of 12 to 19 kilotons.

With these technologies, ABB is driving major efficiency improvements for industry, cities and transport. In 2021, ABB Motion launched the Energy Efficiency Movement. The goal of this multi-stakeholder initiative is to raise awareness of how advanced technologies can mitigate climate change and propel collective action to reduce global energy consumption.

Close case study

We intend to achieve this target by equipping our customers with innovative solutions from all areas of our business. Our portfolio includes such energy-efficient innovations as robots equipped with regenerative braking and software for smart energy management, electric propulsion systems that can substantially reduce the emissions of ships, and cutting-edge technologies to detect methane leaks. Our advanced automation, digitalization and electrification solutions support traditionally energy-intensive industries on their journey to more sustainable operations.

Among our most important technologies for reducing energy consumption are our intelligent motion solutions, including variable speed drives for electric motors, which enable significant electricity savings. We also facilitate the reduction of emissions from cars, buses and heavy trucks with our market-leading portfolio of infrastructure solutions for AC and DC electric vehicle charging. And, crucially, we support the energy transition with technologies that integrate power from intermittent renewable sources into the electricity grid.

ABB’s Process Automation Business Area’s integrated automation, electrification and digitalization solutions have a central role to play in enabling more sustainable operations in the heavy industries. For customers in process, marine and hybrid industries, Process Automation’s offerings – which include such ABB technologies as distributed control systems, marine propulsion, high-power rectifiers and data analyzers – enable their operations to be more productive while reducing environmental impacts.

In 2021, Process Automation’s Process Industries Division launched ABB Ability™ eMine – a purposeful approach and an integrated portfolio of electrification and digital systems to electrify mining processes, from hoisting and grinding to hauling and material handling. As an example of what it achieves, the pilot technology eMine™ FastCharge is set to be the world’s fastest and only fully automated charging system for mining trucks, offering up to 600 kW of power when it comes to the market. Process Automation is working closely with original equipment manufacturers Stäubli and MEDATech to ensure the requisite infrastructure is available for the sector to electrify a wide range of equipment, from drills to excavators and loaders. This infrastructure also includes solutions such as the eMine™ Trolley System, which can reduce diesel consumption, and thus GHG emissions, by up to 90 percent with trolley-assisted hauling, compared to diesel-only operations.

Drawing on ABB’s 130 years of experience in the mining industry, eMine™ provides integral design planning that serves to maximize the value of electrification. By fully integrating electrification and digital systems from the mine to the port, eMine™ reduces CO2 emissions as well as costs, promotes health and safety, and improves mine performance. It is underpinned by ABB Ability™ MineOptimize, a platform that optimizes the design of the plant or mine and facilitates the transition to the digital, CO2-free mine of the future.

As an example of how Process Automation is making shipping more sustainable, the Business Area's Marine & Ports Division is working to deliver an integrated electric propulsion system and advanced vessel control technology for the pioneering eWolf tugboat being built for Crowley Maritime in the United States. Commissioned to support ship arrivals and departures in California’s Port of San Diego, the eWolf will be the first all-electric, battery-powered harbor tug ever built and operated in the US, and the third of its kind in the world. The solution will include a 6 MWh energy storage system, providing power to the propulsion system almost instantaneously, making ship-assist operations more efficient and emission-free. The battery lets the tug complete a full day of typical work before needing to recharge, while the vessel’s all-electric propulsion system is expected to eliminate the equivalent of over 3,100 metric tons of CO2 emissions over its first 10 years of use.

Close case study

In 2021, we identified a basket of these and other high-impact products, services and solutions from our portfolio that deliver substantial reductions in GHG emissions for our customers. Based on sales of ABB offerings from this basket in 2021, we calculated that they will enable our customers to reduce their GHG emissions by 11.5 megatons after the first year. The methodology for this assessment has been verified by a third party. Assuming a conservative 10-year lifetime for these offerings, the 11.5 megatons of annual savings would lead to a cumulative reduction of more than 100 megatons of GHG emissions over the 2021-2030 period from products sold in 2021 alone.

Applying the same logic to our 2030 target of 100 megatons of GHG emissions saved annually by our customers, the total impact of our products sold in 2030 will represent an emissions saving of over 1000 megatons (using the same 10-year average lifetime). In the coming years, we expect savings of GHG emissions from our offerings to increase as new products and solutions are added to the basket.

The process of estimating emissions reductions related to the use of our products, services and solutions is not without its challenges. The precise impact of ABB’s solutions on GHG emissions depends heavily on the operational profile of a particular customer’s assets. In 2022, we will seek to improve our estimates, not only by developing stronger internal GHG measurement methodologies, but also by working with our customers to facilitate the joint management of emissions data. To understand the methodology for calculating this target, please view the page "2030 targets explained" in this report.

ABB Electrification’s E-mobility Division is a world leader in electric vehicle charging infrastructure, offering a full range of charging and electrification solutions for electric and hybrid-electric cars, buses, vans and trucks. ABB entered the e-mobility market in 2010 and as of December 31, 2021, has sold more than 500,000 electric vehicle chargers across more than 85 markets; these include over 25,000 DC fast chargers and 500,000 AC chargers, including those sold through Chinese EV charging company, Chargedot, in which ABB holds a majority stake.

As governments around the world enact policies that favor electric vehicles and charging networks in order to combat climate change, ABB in 2021 launched the world’s fastest all-in-one electric car charger, the Terra 360, which can add up to 100 kilometers of range to a vehicle in less than three minutes. To meet the growing demand for EV charging infrastructure that is fast, convenient and easy to use, the Terra 360 can simultaneously charge up to four vehicles, making it ideal for charging private vehicles as well as fleets of cars, vans and trucks.

ABB’s high-power chargers are being deployed around the world through the company’s partnerships with international charging operators such as IONITY and EVgo. Capable of charging both commercial and passenger vehicles that use any of the major charging standards, ABB’s high-power chargers will support the new GRIDSERVE Electric Highway charging network now being built in the United Kingdom.

In 2021, ABB Electrification entered an agreement with Norway’s largest grocery wholesaler, ASKO, and its owner, NorgesGruppen, to supply charging infrastructure for its growing fleet of electric trucks. ASKO plans to achieve zero-emission distribution of its groceries by 2026. The first ABB HVC 150C (150 kW) high-power chargers are already in operation at ASKO’s distribution center in Oslo, charging two battery-electric trucks, with many more to come. Deploying the ABB Ability™ offering of digital solutions and services, the chargers offer web-enabled connectivity that allows network operators to perform remote monitoring and configuration of charge points, thereby minimizing downtime and increasing efficiency. Norway has itself installed more than 1,000 ABB fast chargers during the last decade as part of its EV infrastructure.

The successful transition from traditional combustion engine vehicles to electric vehicles will depend on the deployment of reliable, widespread charging infrastructure. But building new charging stations can also require new connections to electric grids. Solutions from ABB can strengthen the distribution network by integrating renewables, energy storage and energy management, which can then be coupled with future-proof EV chargers that will be ready for the next generation of electric vehicles.

Close case study

To help our customers leverage the full benefits of our products and services for their operations, we stay in close communication with them whenever possible. Our EnergySave Calculator is among the engagement tools that ABB relies on for this purpose. It helps customers calculate how much energy and money they could save by using variable speed drives from ABB. EnergySave offers a user-friendly way to compare modern AC drive controls with traditional flow control methods found in a range of applications, such as pumps, fans and compressors. The algorithms deployed by the calculator are refined and enhanced on an ongoing basis, with input from pump and fan manufacturers, to ensure a high level of accuracy.

ABB’s Robotics & Discrete Automation Business Area serves a diverse range of industries, from automotive and electronics to logistics, with innovative solutions that help reduce GHG emissions. It achieves this by enabling higher productivity, reductions in production waste, and improvements in product quality and durability.

In 2021, Robotics & Discrete Automation’s state-of-the-art PixelPaint robotic non-overspray technology was recognized with an Innovation and Entrepreneurship in Robotics & Automation Award for Outstanding Achievement. PixelPaint’s inkjet technology conserves resources by eliminating overspray. By increasing the productivity of customized paint jobs by 20 to 100 percent, it significantly reduces the CO2 emitted from painting processes used by the automotive industry.

The Business Area’s pioneering robotics, machine automation and digital services also enable a low-carbon society by allowing ABB’s customers to efficiently produce some of the key technologies needed to reduce emissions and save energy and resources. For instance, automated production processes developed by ABB and Absolicon have radically reduced the cost of producing high-quality solar collectors, making it possible for solar energy to compete with conventional heating. At Absolicon’s factory in Härnösand, Sweden, a robotic production line now uses two ABB robots to produce a solar collector panel every six minutes; previously, the line produced only three units a day using manual methods.

The project’s next phase will supply complete robotic production lines to manufacturers across the globe to help make sustainable solar energy a viable form of heating worldwide. The first installation has already been delivered to a customer in China, and framework agreements for new production lines have now been signed with businesses in a dozen countries.

In 2021, ABB Robotics & Discrete Automation partnered with Intelligent City, which is seeking to transform the world’s foremost source of greenhouse gas emissions – the construction industry. On the company’s shop floor in Vancouver, Canada, ABB robots process, handle and assemble large sections of timber in a production line for prefabricated structural modules that can be used to construct buildings up to 18 stories tall. This solution also makes use of ABB’s RobotStudio offline programming software to plan tasks and movements and to design the factory and the production line.

Robotic automation offers significant potential to enhance productivity, efficiency and manufacturing flexibility throughout the construction industry, including automating the fabrication of modular homes and building components off-site, robotic welding and material handling on building sites and robotic 3D printing of houses and customized structures. As well as making the industry safer and more cost effective, robots are improving sustainability and reducing environmental impact by enhancing quality and cutting waste.

Close case study

Reveal case study

Reveal case study