Customer emissions

Our leading electrification and automation technologies help our customers reduce and avoid GHG emissions

Our greatest contribution to a low-carbon society comes from our energy-saving and emissions-reducing technologies. Among our many impactful offerings are energy-efficient motors and drives, which are in use across industry, buildings and infrastructure, and electric vehicle (EV) charging systems, which enable the shift from combustion cars to EVs. Further contributions are made by our automation technologies, which increase the energy efficiency of industrial operations and facilitate the reliable integration of renewable energy sources into the energy mix, among other purposes. Digital solutions from ABB help customers design and deploy such integrated, energy-efficient systems in a cost-effective manner. In this section, we highlight some of the ways in which we are helping our customers reduce and avoid emissions in sectors that account for the majority of global energy consumption.

Energy savings enabled by ABB motors and drives

Significant energy savings are enabled by our variable-speed drives for electric motors. They regulate the amount of power that is fed into a motor to match the load it must perform, thus avoiding excess use of energy. By adding a drive to an existing motor system (retrofit), energy savings of up to 25 percent are possible. Upgrading a drive to a newer model can deliver single-digit percentage energy savings, while replacing a motor and drive system with a newer model typically enables energy savings of around 1 percent.

To calculate the energy savings that ABB motors and drives enable for our customers, we considered the most impactful applications for these offerings and compared them with a typical or “base” scenario that represents the energy that would be consumed in the absence of the ABB offering. The most impactful applications are pumps, fans and compressors, which account for 45 and 80 percent respectively of all ABB low- and medium- voltage drives sold. As a rule, the larger the motor, the more energy the drives save.

Technologies for industry

Industry consumes more energy than any other sector and emits 24 percent of global GHG emissionsIPCC Climate Change 2022: Impacts, Adaptation and Vulnerability; Working Group II Contribution to the Sixth Assessment Report, p. 88 of pdf. The bulk of electricity used in industry is consumed by industrial electric powertrains, which typically consist of a motor, a variable-speed drive and an application, such as a pump, fan or compressor.

In Brazil, ABB drives, motors and smart sensors enabled water and wastewater company Saneago to reduce its electricity consumption by roughly 25 percent in 2022. Our process automation and control systems continue to deliver energy savings for customers in industries that address a wide range of essential needs – from supplying power, water and other basics to manufacturing goods and transporting them to market. The intelligent power solution we supplied to the Kangsheng Data Center in Beijing will support its goal of becoming a “low-carbon and green data center,” putting it on track to save up to 20 percent in utility costs and 30 percent in operational costs.

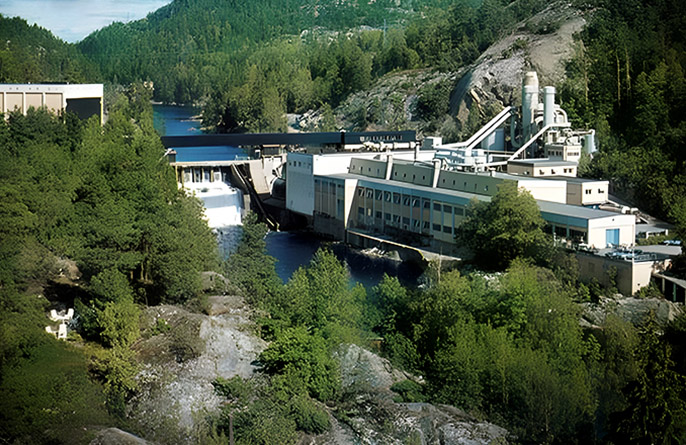

Case study Eliminating 14,000 tons of annual GHG emissions at a pulp plant in Norway

Reveal case study

Reveal case studyIn 2022, we provided our industrial customers with a range of digital solutions that help them monitor and optimize their energy consumption and emissions footprints. Fiorentini, a major Italian snack manufacturer, is using ABB Ability™ Energy Manager to monitor almost 100 intelligent devices and control the electrical power distribution in its new 56,000-square-meter production facility in Trofarello. This solution will help Fiorentini make better-informed performance and energy consumption decisions, in keeping with its commitment to reduce its use of electricity by 400,000 kWh per year. Digital solutions such as the ABB Ability Digital Powertrain are also being used by CERN, Europe’s foremost nuclear research center, as part of a project intended to improve the energy efficiency of its cooling and ventilation infrastructure by up to 15 percent.

Looking ahead, we have expanded our partnership with Hydrogen Optimized to advance the deployment of economical, large-scale, green hydrogen production systems. We expect such systems to play a vital role in the decarbonization of essential but hard-to-abate industries such as utilities, metals, cement, ammonia and fertilizers, as well as to provide clean fuels for aircraft, ships, trucks and railway engines.

Technologies for the buildings sector

Buildings account for 5.6 percent of global GHG emissions.IPCC Climate Change 2022: Impacts, Adaptation and Vulnerability; Working Group II Contribution to the Sixth Assessment Report, p. 88 of pdf ABB is supporting the effort to reduce the emissions of this sector with technologies that can increase the energy efficiency of existing structures and radically reduce the emissions footprint of new structures that are purposely designed to conserve energy.

In 2022, ABB and Caverion, a northern and central European-based company specializing in smart and sustainable built environments, entered an agreement to accelerate the development of carbon-neutral buildings by combining the two companies’ solutions, integration capabilities and expertise. This collaboration is directly linked to ABB’s Mission to Zero™ program, which seeks to help customers achieve carbon neutrality by leveraging energy management solutions associated with electrification, distributed energy and renewable energy. Also in 2022, ABB Electrification and Samsung Electronics forged a global partnership to supply jointly developed technologies for energy savings, energy management and the Internet of Things (IoT) for use in residential and commercial buildings.

Case study BREEAM green building certification: designing more sustainable buildings

Reveal case study

Reveal case studyTechnologies for the power sector

The power sector is responsible for 23 percent of global GHG emissions.IPCC Climate Change 2022: Impacts, Adaptation and Vulnerability; Working Group II Contribution to the Sixth Assessment Report, p. 88 of pdf To help reduce its emissions, ABB has developed solutions that not only support the transition to renewable energy, but also maximize the efficiency and reliability of power facilities through the automation, integration and optimization of the entire plant.

One of the most significant GHGs associated with the power sector is sulfur hexafluoride (SF6), a commonly used insulating gas that is 23,500 times more potent than CO2. ABB’s ecoGIS™ range of products is enabling customers like Enel and UK Power Networks to reduce their emissions by phasing out switchgear that uses SF6. To support customers’ energy transition, ABB also supplies innovative solutions for the integration of renewable energy. For example, ABB Ability™ Electrification Monitoring and Control, ZEE600 software and ABB Ability™ Smart Substation Control and Protection for SSC600 electrical systems can handle the intermittency associated with renewable energy resources. That is why they were installed in 2022 at a substation near India’s Anabaru windfarm. In Italy, Enel Green Power upgraded its 60 MW geothermal plant in Farinello – part of the oldest geothermal complex in the world – with ABB’s state-of-the-art medium-voltage VD4G generator circuit breakers, reducing outages. These circuit breakers provide full protection for this major source of renewable energy relied upon by the residents of Tuscany. In India, we supported the efforts of THINK Gas, which is working to shift India’s energy sector from coal, oil and firewood to gas; we supplied the company with our SCADAvantage™ and ABB Ability™ Genix Industrial Analytics and AI suite to increase the efficiency, availability and reliability of its city gas distribution network.

Technologies for the transport sector

Transport accounts for 15 percent of global GHG emissions.IPCC Climate Change 2022: Impacts, Adaptation and Vulnerability; Working Group II Contribution to the Sixth Assessment Report, p. 88 of pdf To help decarbonize this vital sector, ABB is supporting the transition to electric mobility. In addition to providing charging solutions for vehicles such as passenger cars and buses, we also offer solutions to electrify the powertrains of trains and marine vessels.

In 2022, we continued to support the adoption of EVs around the world, having now sold more than 840,000 electric vehicle chargers in more than 85 markets. Our work included signing a new global framework agreement with Shell to supply our full portfolio of charging solutions. As part of this agreement, we announced the launch of Germany’s first nationwide charging network, using ABB Terra 360 chargers. The Terra 360, recognized by Time magazine as one of the best inventions of 2022, is not only one of the fastest electric car chargers in the world but also the most flexible one. It is capable of fully charging an electric car in 15 minutes and can charge up to four vehicles simultaneously, making it ideal for fleet operators. We also partnered with PACCAR, a designer and manufacturer of premium trucks, to provide advanced charging solutions for its fleet operations in North America and Europe. And in line with our commitment to facilitate progress in this sector, we worked with CharIN and other organizations to promote the adoption of heavy-duty all-electric vehicles by jointly developing a standard for the Megawatt Charging System, which is expected to debut in 2024.

In the rail sector, we are supplying a 25 kV power solution for Lithuanian Railways that will be used to electrify 730 kilometers of a fully carbon-neutral rail line. And in Australia, we are providing the Adelaide Metro with a lithium-ion-based energy storage system that will make better use of energy from regenerative braking systems; the solution is expected to reduce electricity consumption by up to 16 percent.

In the marine transportation segment, we have continued to drive the decarbonization of ships with our electric, digital and automation solutions. Among our many projects in this sector, we will supply and integrate advanced power, automation, control and energy-storage systems for two next-generation installation vessels ordered by Eneti, a company specializing in offshore wind turbine construction. In the port of Toulon, we are leading a turnkey project to build the largest ship-to-shore solution in France, which will cut emissions and noise pollution for ferries and cruise ships during port stays.